8×12 Lean To Shed Plans For Lovely Garden Shed

Once you have finished building this shed, you will have a cozy new place for storing your yard tools in an organized manner. It will also help you clean out some of your garage items and get some much-needed space.

This shed has a traditional look, and it has clerestory windows, which allow ample natural lighting into the shed.

It has a lot of wall space for hanging your equipment and putting up shelves.

Here are the essential steps involved in making this shed.

8?12 Lean To Shed Plans For Building Floor & Wall Frame

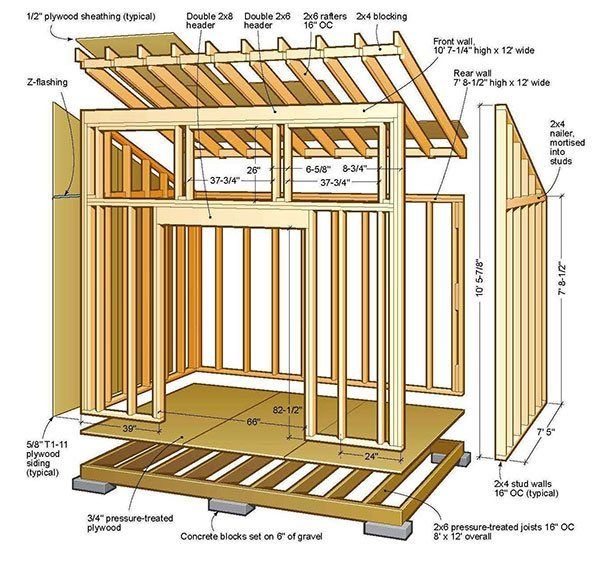

Foundation and Floor

- Begin by building the perimeter—thrust stakes made from 2x4s into each corner of the shed foundation.

- Measure the lengths of the diagonals to check that the perimeter is accurately square.

- Burrow 6 inch deep openings in the soil for placing the 8-inch x 12-inch footing blocks made of concrete.

- Pack the openings with compacted gravel and then arrange the blocks at their proper position.

- Ensure that each block is level.

- Build the floor using pressure-treated timber. Trim the inner 2?6 headers by about 3 inches as compared to the outer headers.

- Secure the 2x6s such that there is a 1.5-inch notch at both ends of each header joist.

- Trace out the joist hangers’ locations such they have 16 inches on center spacing and then fasten the hangers.

- Layout the floor frame over the concrete foundation blocks and verify that the frame is correctly square and completely level.

- Craft the 2?6 joists and secure them with the joist hangers using galvanized nails.

- Secure the 0.75-inch thick pressure-treated floor made of plywood to the floor frame with 2-inch wood screws.

Wall Frame

- The walls of the shed can be built on the shed floor before hoisting them into position.

- Frame the front wall using 2?4 studs spaced at 16 inches on center.

- The window header is made using a double layer of 2x6s, and the door header using 2x8s.

- Use 0.5-inch plywood spaces for creating the headers.

- Craft the studs, top plates, window studs, and blocking.

- For building the front wall, secure the corner trimmers with the corner studs using nails.

- Trace out the positions for the studs over the first top plate and the soleplate.

- Put together the studs for the section of the lower wall on the shed floor.

- Secure the next top plate over the first top plate using nails and later attach the disabled people for the end window in position.

- Craft and fasten the short blocks over the top plate using nails.

- Toenail the top plate and cripple studs and then fasten the top plate over the cripple studs using galvanized nails.

- Nail the upper 2?6 header into the plate using 10d galvanized nails and then nail into the corner studs using 16d nails.

- Next, secure the blocking for the upper window in place using nails.

- Secure a long brace to the surface of the front wall diagonally so that the wall remains square.

- Fasten two 2?4 blocks to the front of the floor to bracing the front wall in position and prevent it from slipping as you hoist it.

- Secure the soleplate with the floor using nails.

- Take a look at the shed diagrams for understanding the layout and steps for creating the rear wall.

- Notice that small blocks are utilized for creating a triple 2?4 end stud.

- Trace the location on the studs on the soleplate and then fasten the studs in place using nails. Then secure both of the upper plates.

- Like the front and back walls, craft the sidewalls on the shed floor and hoist them into place.

- Place a 2?4 at the rear wall location and then construct the side walls inside the space between the rear 2?4 and front wall.

- Using a friend’s help, hoist the sidewalls into place and fasten them to the front wall.

- Hoist the rear wall and secure it to the side walls.

- Secure the side walls with the shed floor, the rear wall, and the front wall.

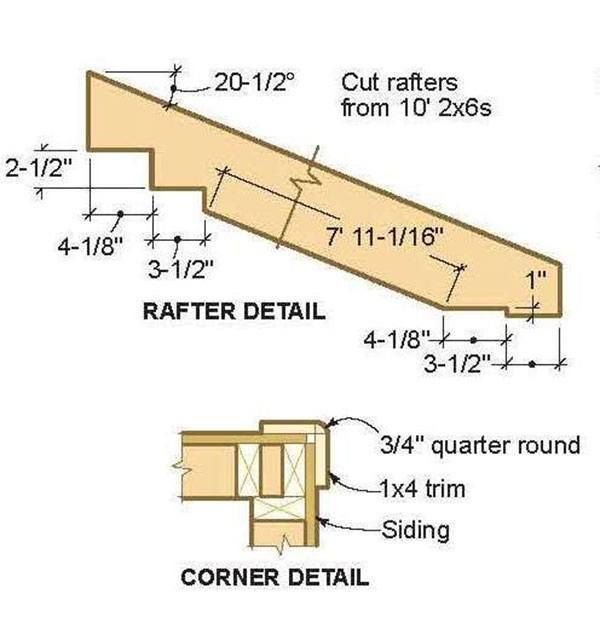

8?12 Lean To Shed Blueprints For Constructing Roof Frame

- You must attach the siding before you start creating the roof because, on the back wall, the rafters overhang the siding.

- Attach 0.625-inch thick siding using 8d nails. You will need 3 sheets of 4?8 siding nailed equally at the upper end of the wall. The siding overhangs 3.5 inches over the floor.

- Use your first rafter as a template for crafting the remaining rafters so that all of them will have similar cuts.

- Trace and cut one rafter using a 2?6 piece of lumber as shown in the diagram and verify that it fits correctly.

- Create and toenail the other rafters into place using galvanized nails.

- Build and secure the 2?4 blocking at the back and front.

- Secure metal anchors to the walls and rafters.

- Attach the leftover siding to the remaining sections of the shed.

- The sides will need 2 complete sheets with their upper boundaries centered over the 2?4 nailer.

- Now fasten Z flashing over these sheets using nails and then cut out the angular upper side sections to fit.

- Note to cut and extract the sole plate at the opening for the door.

- Carve the siding to fit among the windows and then secure the Z flashing over them. Then attach siding on the header above the windows.

- Cut out the door opening and retain the siding pieces for crafting the door later.

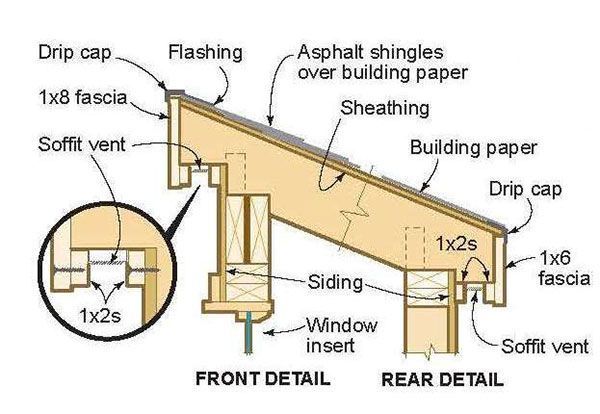

Fascia, Vents, and Roofing

- Cover the roof with 0.5-inch thick plywood and secure it with the rafters using 6d nails.

- Fasten two spacers at the top side and then attach the 1?6 fascia.

- Attach the soffit vents with the bottom overhang of the rafters.

- Secure 1x2s over the upper end of the wall and the vent.

- Fasten a fascia board to the ends of the rafters and attach another 1?2 support for the vent. Secure it to the fascia tightly next to the vent.

- Connect a drip cap to the roof’s back edge and then attach the roofing felt to the roof starting from the lower edge.

- Successive sheets will use 2 inch top laps.

- Once the drip cap is attached over the, felt along the roof’s side boundaries, then lay the shingles.

- Use 8-inch metal flashing to close the rooftop by bending it over the fascia and then add the drip cap.

8?12 Lean To Shed Diagrams For Assembling Doors and Windows

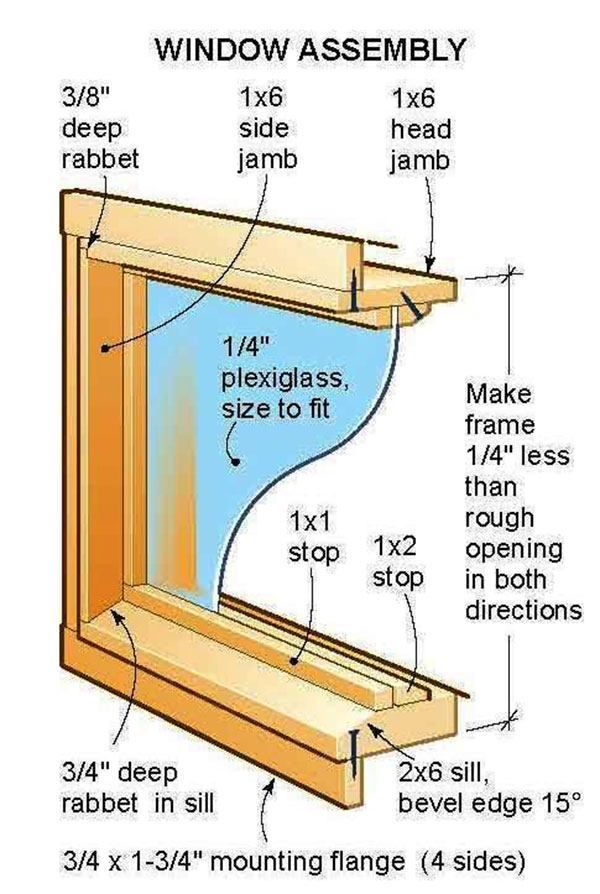

Windows

- The window frames are 0.25 inches smaller than the openings in the wall.

- Cut the jambs and create the sill according to the needed length. At 2.75 inches along the front boundary, the sill has a 15-degree bevel.

- Trace and cut out the 0.75 inch deep rabbets at the ends of sills for the side jambs.

- Now cut 3/8 inch deep rabbets into both ends of the head jamb used for the sides.

- Secure the frame with nails and glue.

- Create and nail 1?1 stops into place.

- Attach the mounting flanges.

- Use 0.5 inches thick clear acrylic for the window glazing of the clerestory windows.

- Make the back edges of the inner window stops smooth to help secure them in place more easily.

- Paint the stops and then put the acrylic inside and screw in the stops.

- Caulk over the face of the siding and then add the windows.

- Secure the flanges with the framing using nails.

Doors

- Use 1?6 timber board for crafting the door jambs.

- Create 3/4 inch x 3/8 inch rabbets inside the side jambs for attaching the top jamb.

- Secure the top jamb into position using nails.

- Secure the stops 2.5 inches behind the front boundary of the jambs.

- Attach 4-inch butt hinges on the side jambs.

- Attach shims to the door frame wherever needed and then secure it to the studs by nailing into the shims.

- Verify that the jambs are flush and plumb with the siding face using a level.

- Secure the top jamb to the header by driving nails into the shims.

- There should be 0.25-inch clearance all around the double doors.

- Create a door by laying out 2x4s half-lapped at the corners.

- Create the frame using 1.25-inch plywood on the front and 0.25-inch thick plywood on the back.

- Attach the 1?4 trim for the door and leave a 0.125-inch reveal.

- Hang the doors from hinges.

- Attach a 1?2 stop on the inner edge of the left door.

- Secure a barrel bolt on the left door and fasten a hasp outside.

Final Touches

- Frame the ramp using 2x4s and cover it with 2?4 decking using 3-inch wood screws.

- Secure a 2?4 ledger over the floor header joist beneath the door opening.

- Excavate a 6-inch deep pit in the ground for containing the ramp and fill it with compact gravel.

- Insert L-shaped cane bolts into the pipes on the ramp sides for holding the door open.

- Attach 1?6 trim near the lower end of the shed to guard the siding against moisture.

- Add 1?4 corner boards to complete the corners.